ULTRALIGHTWEIGHT DESIGN OF A vehicle seat through SYSTEMATIC use of xFK IN 3D™ and additive MANUFACTURING

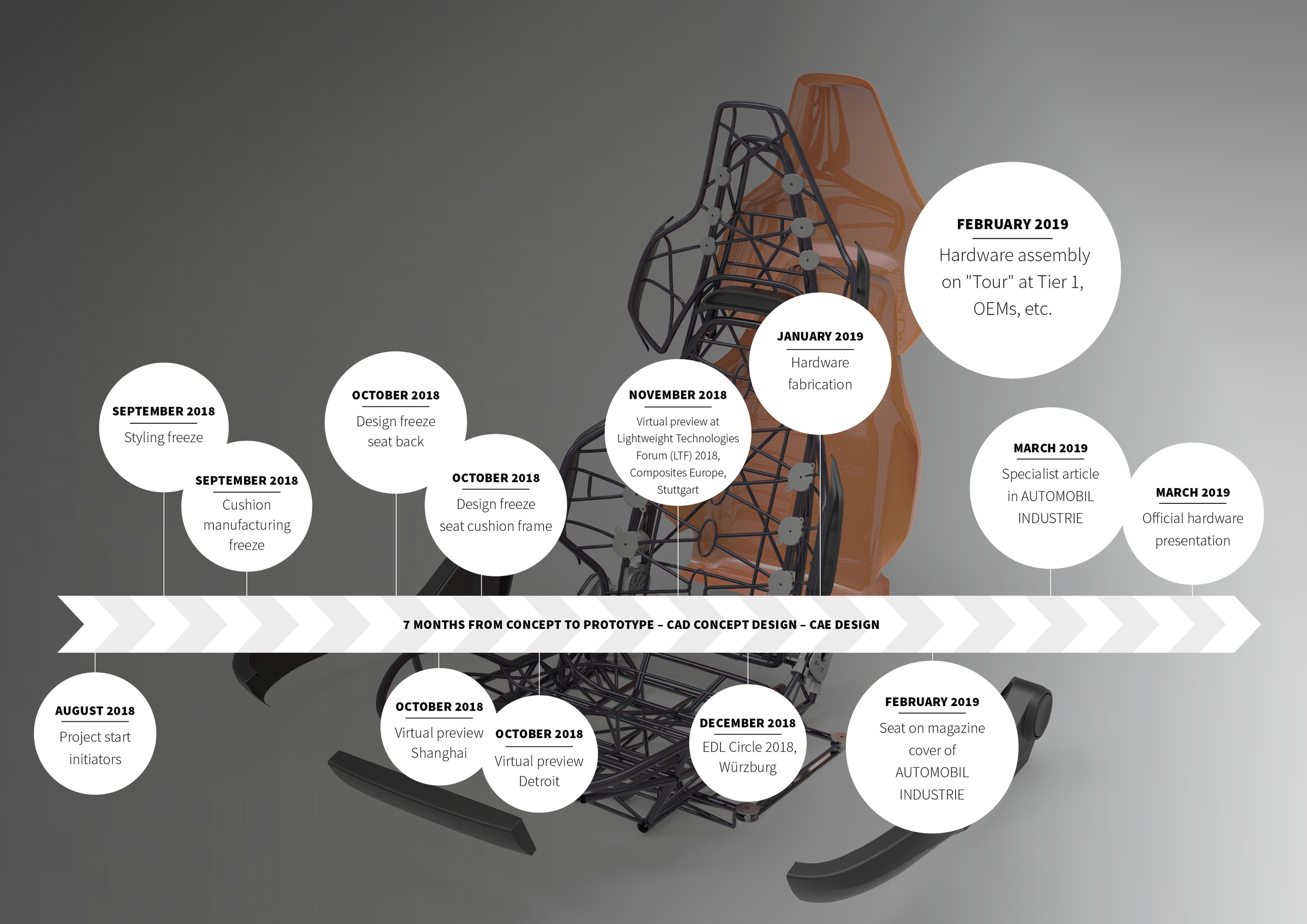

In the project #ULTRALEICHTBAUSITZ a vehicle seat concept (idea of the target markets: hypercar and air taxi) with a weight of 10 kg was completely redesigned. In a 7-month project between 08/2018 and 02/2019 the initiating companies csi entwicklungstechnik, a Germany based vehicle developer, Alba tooling & engineering, a specialist for the development and production of innovative production systems in the field of high-quality plastic components, and the management consulting company AMC developed the virtual and hardware prototype of a seating concept, together with Robert Hofmann GmbH, covestro, 3D|CORE and LBK Fertigung.

Find out more: #ULTRALEICHTBASUSITZ

The innovation

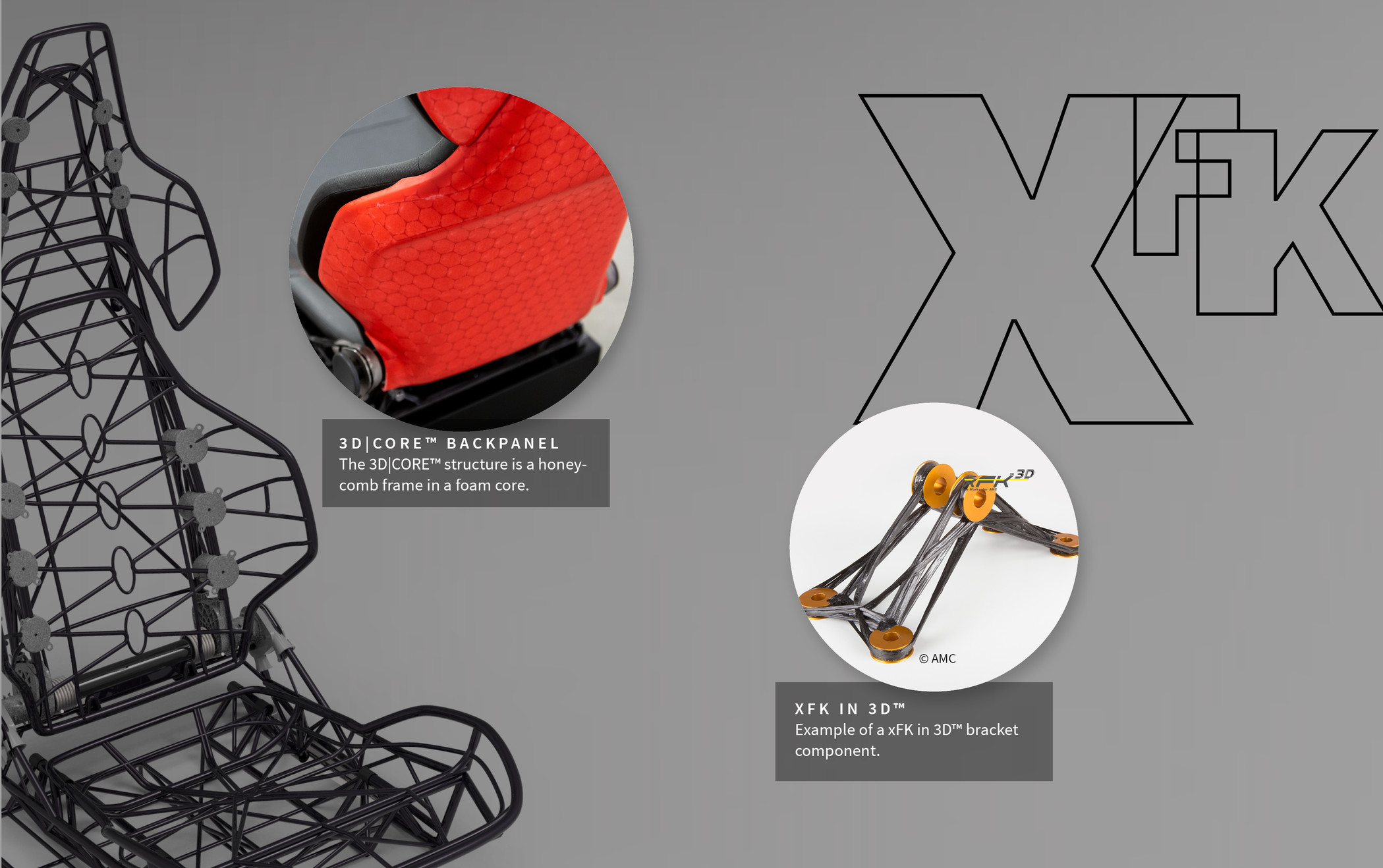

One of the main reasons for the significant weight reduction of the seat is its innovative »xFK in 3D™« hybrid frame structure, which plays together perfectly with the options of metal Additive Manufa-turing. The lightweight philosophy of “having the right material at exactly the right place” and “only as much material as needed” has been perfectly followed here.

The process innovation xFK in 3D is a highly flexible, almost arbitrarily configurable, cost effective and sustainable fiber composite technology for winding components, which has already been designed for a variety of products and applications for various industries and market segments.

xFK in 3D describes a concrete as well as measurable technological contribution to the integrative lightweight construction of the future. When fibers like glass, carbon, basalt and many more natural fibers of composites (»xFK«) are aligned specifically according to the desired component functions and load collectives and manufactured in three dimensions (»xFK in 3D«), spatial, ultralight structural components of high intelligence are created. The advantages of the process are multi-dimensional and range from the fiber deposition in the directions of forces and tension, up to minimal material waste. The highly innovative process technology of AMC thus serves environmental and climate protection, conserving resources and sustainability equally. xFK in 3D is certainly the lightest way to build – »lightweight construction at its finest«.

Further weight reduction is possible through the use of an intra-laminar reinforcing core material 3D|CORE™, which was used for the back panel shell structure of the seat backrest.

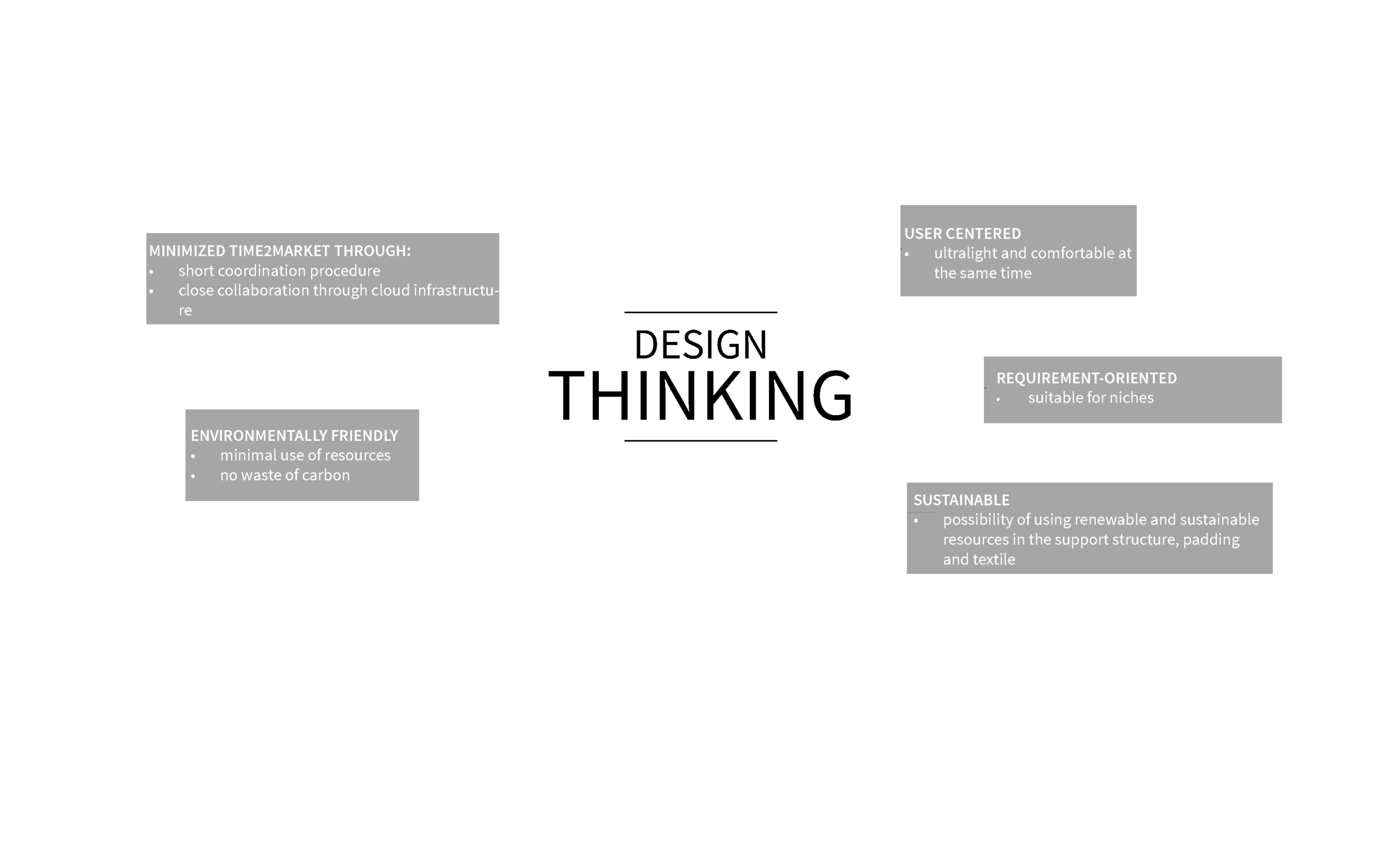

INNOVATION BENEFIT

The process innovation xFK in 3D is a highly flexible, almost arbitrarily configurable, cost effective and sustainable fiber composite technology for winding components, which has already been designed for a variety of products and applications for various industries and market segments.

xFK in 3D describes a concrete as well as measurable technological contribution to the integrative lightweight construction of the future. When fibers like glass, carbon, basalt and many more natural fibers of composites (»xFK«) are aligned specifically according to the desired component functions and load collectives and manufactured in three dimensions (»xFK in 3D«), spatial, ultralight structural components of high intelligence are created. The advantages of the process are multi-dimensional and range from the fiber deposition in the directions of forces and tension, up to minimal material waste. The highly innovative process technology of AMC thus serves environmental and climate protection, conserving resources and sustainability equally. xFK in 3D is certainly the lightest way to build – »lightweight construction at its finest«.

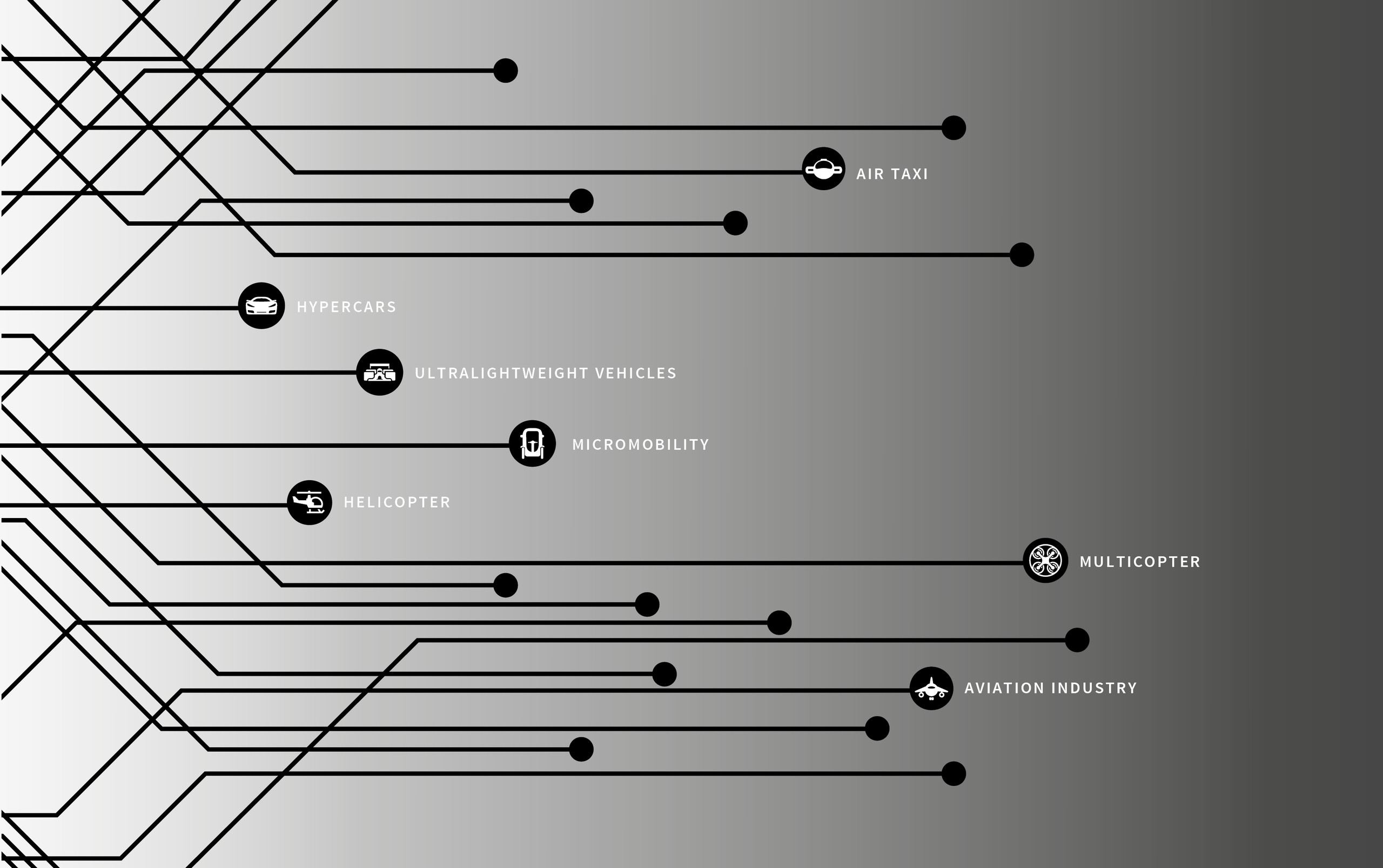

MARKET POTENTIAL

There is no lighter way to build according to the current state of the technology and science than fiber composite single-stranded, e.g. with the xFK we use in 3DTM. Likewise, the 3D-printed connecting parts allow for the theoretically highest limit of lightweight construction. A stable "Competitive Advantage" is given in the shown construction for the next years. The market potential concerns the currently increasingly widespread hypercars (McLaren, Le-Mans-road versions, etc.) and future hybrid intermodal (flying and traveling) solutions such as air taxis or the like. The #ULTRALEICHTBAUSITZ as a niche product is consistently tailored to the requirements of these applications.

DIGITAL PROCESS CHAIN

AREAS OF APPLICATION

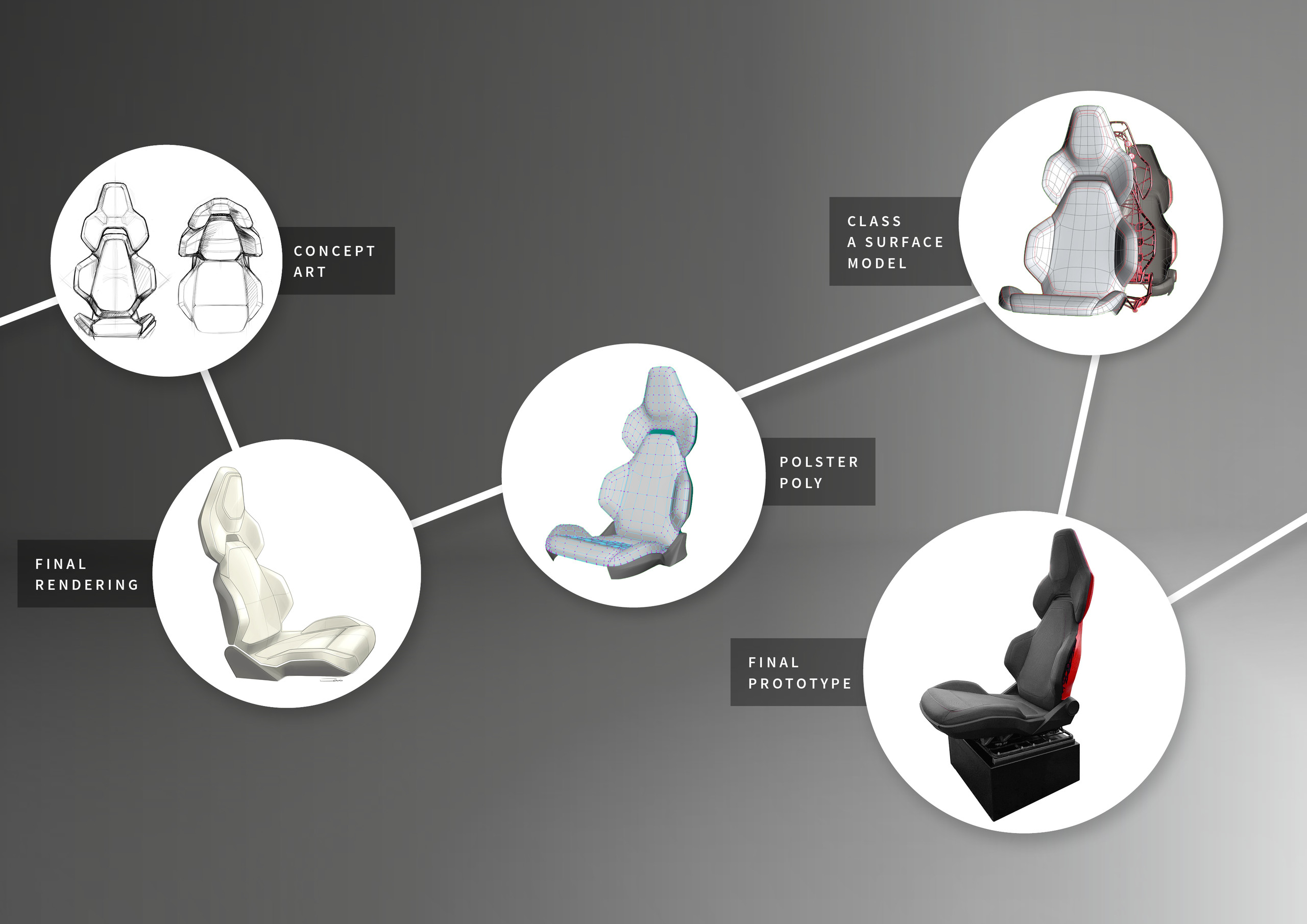

Styling process

From Concept to prototype Hardware

Covestro